-

SOFTWARE

SOFTWARESAP HCM & PayrollQuery Manager Query Manager Add-ons Document Builder Variance Monitor DSM for HCM HCM Productivity Suite FLOW GeoClockSAP Landscape & Test Data ManagementData Sync Manager (DSM) suite - System Builder/Shell Sync - Object Sync - Client Sync - Data Secure Archive CentralSupport & TrainingClient Central E-learning & trainingSAP Data Privacy & SecurityData Privacy suite - Data Secure - Data Disclose - Data Redact - Data Retain Soterion (GRC)

-

SERVICES

SERVICESSAP HCM & PayrollPRISM for HR & Payroll SAP SuccessFactors Integration monitoring Payroll reporting Report writingClient-specific DevelopmentCustom development SAP BTPSAP Landscape & Test Data ManagementPRISM Migrations to S/4HANA System Landscape Optimization (SLO) Managed data refresh servicesSAP Data Privacy & SecuritySAP data privacy assessment serviceMass data removal services Data privacy consultingCloud and Application Managed ServicesFunctional AMS Cloud management services Cloud migrations Basis managed services Private cloud hosting SAP on AWS SAP on Azure Premium Support Services RISE BRIDGE Managed Services

- All Solutions

- Request Estimate

-

Resources

Resources Blogs Read the latest updates on SAP SLO, SAP HCM, Data & Privacy, and Cloud Webinars Access expert insights in live and recorded webinars Video library Watch videos and improve your SAP knowledge

- About

Data Sync Manager captures Edwards’ SAP testing and training needs

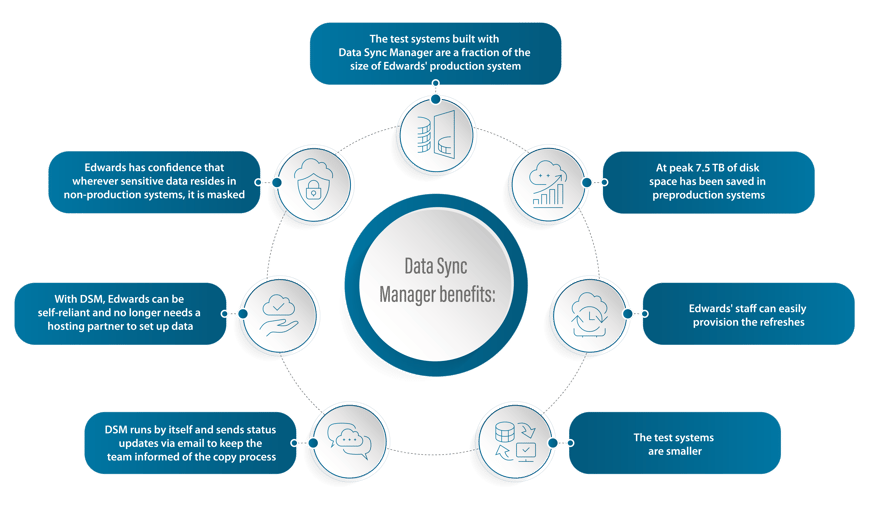

Test systems are a

fraction of production

system size

More than 7.5TB of

disk space saved in

pre-production

DSM is self sufficient-

sends status updates

via email

About Edwards

Edwards is a leading developer and manufacturer of sophisticated vacuum products, abatement solutions and related value-added services. The products are integral to manufacturing processes for semiconductors, flat panel displays, LEDs and solar cells and are used within an increasingly diverse range of industrial processes including power, glass and other coating applications, steel and other metallurgy, pharmaceutical and chemical; and for both scientific instruments and a wide range of R&D applications.

Edwards' SAP test data challenge

Edwards was increasingly challenged with managing SAP® data in its non-production environments. In an interview with Mike Ellis, Software Development Technical Manager at Edwards, he explains their situation:

“We were running multiple projects in parallel, each needing independent testing in isolation on production data. At peak there were requirements for four additional test systems - one with two clients - each full copies of production, which of course led to an escalation in disk space cost. The restore and post-processing took about a week per system, and also required work by our hosting partner.”

Having to move manufacturing into SAP was a key driver to start investigating alternative methods for copying data. Edwards had built a second development system, so that the business could be supported as usual, whilst the main manufacturing project was developed and tested in the standard landscape. These test systems did not require full copies of production, but subsets of data, so EPI-USE Labs was approached with three key requirements:

- The need to build new training CRM/ECC systems

- The need to build a new test development client

- The need to build small test systems.

It is possible to test and retest and refine the conversion of manufacturing systems

... it is possible to refresh over a weekend

The business case

“Everyone was really impressed with Data Sync Manager and internally we set about our justification case. Edwards based the business case on reducing our test system from 1.4 TB to 600GB and needing a second test system for our manufacturing project. We had a regulatory requirement to scramble sensitive data too”.

Edwards purchased DSM Client Sync and DSM Data Secure for SAP ERP and CRM. Client Sync provides a table-oriented approach to copying a subset of a client while Data Secure masks sensitive data.

How it all works at Edwards today

Using Production as their source system, Edwards kicks off an extract on a Saturday night with as much processing power as can be given. DSM writes to Unix tables (in Edwards’ case to the transport directory so that the tables can be seen by all the systems in the landscape) and, depending upon the amount of data required, the extract takes between 5 and 18 hours to complete.

On the Monday the import starts. It usually takes double the time to refresh the system, primarily because Edwards’ test systems are smaller than production, which means that only half the number of batch processors can be used. All jobs can be set up in advance and scheduled via DSM Client Sync’s Monitor Desk. Using DSM obviates the need for hosting partners (and cuts attendant costs) because Edwards is able to do everything themselves.

Extracts can be re-used – in the case of the conversion system, the system was refreshed three times with the same data. It is possible to test and retest and refine the conversion of manufacturing systems. Multiple extracts are held in Unix so that it is possible to refresh over a weekend if needed.

How DSM changed training systems

Previously the training strategy depended on two clients: a “Golden” client and a training delivery client. Each weekend Edwards’ hosting partners would perform all the manual steps, such as BDLS, and rebuilding links, etc. If the training was taking place in Asia then the processes would have to be done on the Sunday in order to get the manual steps completed in time.

The end result is that Edwards is now able to rebuild and populate their training systems without relying on an offshore company to manually set up the data. By using a subset of production data, the training system is more realistic for the users.

DSM has had a profound effect on our procedure. It was used to rebuild the “Golden” client after which the external links were set up. Having built the training system, a DSM copy of the entire system was made to Unix, which reduced a 320GB system to 60GB. Now, whenever a training refresh is needed, it can be scheduled via the Monitor Desk and takes approximately 8 hours to refresh. There is no post-processing and the costs of 260GB of disk are saved!

Outcome: huge savings every year

By reducing the size of the test and non-production systems, Edwards saved approximately £30,000 per annum. They were also able to build a new system for a project without having to rent additional disk space, which saved approximately £10K from the project costs.